- Home

- About Us

- BEVS

- BEVS – Viscosity

- BEVS- Film Applicators

- Automatic Panel Sprayer

- Mini Automatic Film Applicator

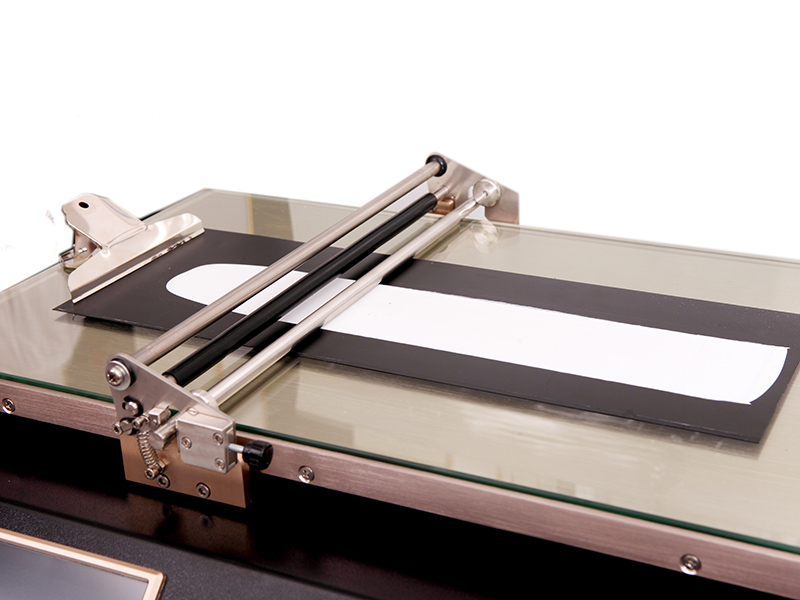

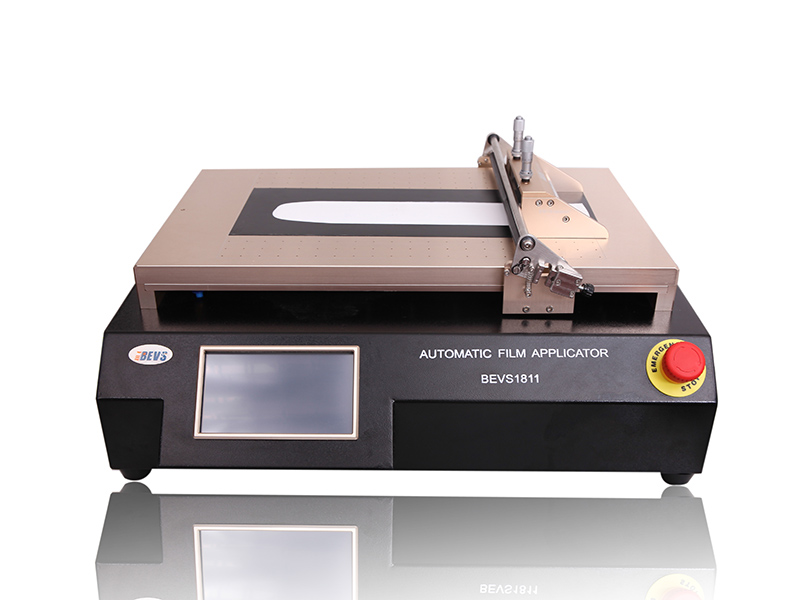

- Automatic Film Applicator

- Digital Adjustable Applicator

- Bar Coater

- Bar Coater Handle

- Four Sided Applicator

- Eight Sided Applicator

- Adjustable Applicator

- Levelling Applicator

- Sagging Applicator

- Cube Applicator

- Four Sided Applicator With Reservoir

- Two Sided Applicator

- Single Sided Applicator

- Hiding Power Chart

- Film Application Kit

- BEVS-Drying time

- BEVS-Thickness

- BEVS-Color/Gloss

- BEVS-Adhesion

- BEVS-Hardness

- BEVS-Deformation

- BEVS-Abrasion, Scrub / Washability

- Viscometers

- Flow Cups

- Calibration Oils

- Guide

- Contact Us